- MACH4 system

- Supports MAX 6-axis

- Maximum step-pulse frequency is 2000KHz

-

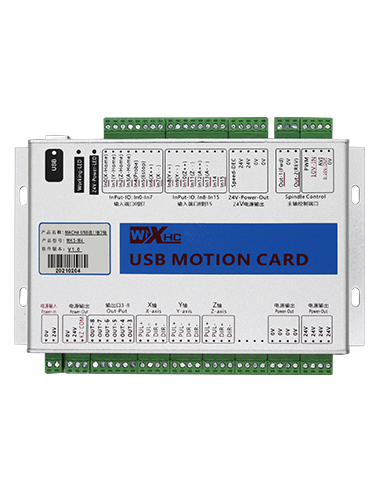

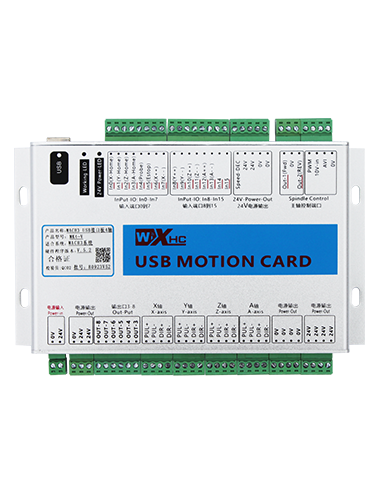

Application software: MACH4 Application Control card application industry :CNC cutting machine. CNC router.Machining Center.Mechanical arm.Automated production equipment. Features: 1.Fully supporting all Mach4 versions 2.Full support for USB hot-swappable, the card is Monitoring USB connection status at any time. 3.Supports MAX 6-axis 4.Maximum step-pulse frequency is 2000KHz 5. Status indicator LED can be useful to show the USB connection, and working stauts by flashing. 6.16 input IO+8output IO, support spindle feedbackfunction, support difference output. all IO-port isolation, interference, stable performance

Application software: MACH4 Application Control card application industry :CNC cutting machine. CNC router.Machining Center.Mechanical arm.Automated production equipment. Features: 1.Fully supporting all Mach4 versions 2.Full support for USB hot-swappable, the card is Monitoring USB connection status at any time. 3.Supports MAX 6-axis 4.Maximum step-pulse frequency is 2000KHz 5. Status indicator LED can be useful to show the USB connection, and working stauts by flashing. 6.16 input IO+8output IO, support spindle feedbackfunction, support difference output. all IO-port isolation, interference, stable performance -

Model: WHB04B-4 4 Axis WHB04B-6 6 Axis Application software: MACH3 Application Control card application industry :CNC cutting machine. CNC router.Machining Center.Mechanical arm.Automated production equipment 1.Radio Frequency: 433MHZ,ISM,TX power 10DB,RX sensitivity -98DB 2.100pulse per round MPG, support 10 customs key buttons 3.LCD monitor will display X/Y/Z/A/B/C mechanical and workpiece coordinates, support 3 axis coordinates display in one time RF support 64 channels, Each channel gap 1Mhz 4. Support Frequency hopping transmission, Stable and reliable 5.One room can run 64pcs MPG at the same time, and will not affect each other due to frequency hopping function 6.100PPR MPG function, customs macro function keys up to 10pcs

Model: WHB04B-4 4 Axis WHB04B-6 6 Axis Application software: MACH3 Application Control card application industry :CNC cutting machine. CNC router.Machining Center.Mechanical arm.Automated production equipment 1.Radio Frequency: 433MHZ,ISM,TX power 10DB,RX sensitivity -98DB 2.100pulse per round MPG, support 10 customs key buttons 3.LCD monitor will display X/Y/Z/A/B/C mechanical and workpiece coordinates, support 3 axis coordinates display in one time RF support 64 channels, Each channel gap 1Mhz 4. Support Frequency hopping transmission, Stable and reliable 5.One room can run 64pcs MPG at the same time, and will not affect each other due to frequency hopping function 6.100PPR MPG function, customs macro function keys up to 10pcsLCD mon itor display:Spindle speed value, processing feed rate value

- Support MACH3 system

- support 10 customs key buttons

- Wireless distance of 40 meters

-

Application software: MACH4 Application Control card application industry :CNC cutting machine. CNC router.Machining Center.Mechanical arm.Automated production equipment. Features: 1.Fully supporting all Mach4 versions 2.Full support for USB hot-swappable, the card is Monitoring USB connection status at any time. 3.Supports MAX 6-axis 4.Maximum step-pulse frequency is 2000KHz 5. Status indicator LED can be useful to show the USB connection, and working stauts by flashing. 6.16 input IO+8output IO, support spindle feedbackfunction, support difference output. all IO-port isolation, interference, stable performance

Application software: MACH4 Application Control card application industry :CNC cutting machine. CNC router.Machining Center.Mechanical arm.Automated production equipment. Features: 1.Fully supporting all Mach4 versions 2.Full support for USB hot-swappable, the card is Monitoring USB connection status at any time. 3.Supports MAX 6-axis 4.Maximum step-pulse frequency is 2000KHz 5. Status indicator LED can be useful to show the USB connection, and working stauts by flashing. 6.16 input IO+8output IO, support spindle feedbackfunction, support difference output. all IO-port isolation, interference, stable performance- MACH4 system

- Supports MAX 6-axis

- Maximum step-pulse frequency is 2000KHz

-

1. Provide DLL library file for Windows 2. Provide VC example programs for electronic handwheel applications, including VC source code 3.USB interface, adopt USB1.1 full speed transmission 4. Customer secondary development 5. Provide 128 * 64 dot matrix LCD display, customers can download the display content through DLL 6. Provides 32 key inputs 7. Provide 100PPR electronic handwheel input 8. Barrier-free operating distance: 40 m 9. Patented XHC wireless transmission protocol; automatic frequency hopping, strong anti-interference ability 10. Low power consumption design: 2 AA batteries, use time 30 days 11.32 sets of equipment, simultaneous use does not affect 12. Industrial-grade design, dust-proof design, stable and reliable.

- Provide DLL library file for Windows

- Provide VC example programs for electronic handwheel applications, including VC source code

- Secondary development

-

Application:Welding machine automation welding and welding operator.Turn Rolls

1.Use 433MHZ wireless transmission frequency .long distance wireless frequency hopping technology .wireless control distance 200m without barrier 2.In the same working area,it can support 32pcs equipments used at the same time 3.LCD monitor can display present welding current ,voltage and speed 4.Support 4lines 250v/3A relay output.to control contactor achieve motor clock wise/counter-clock wise 5.Support 1lines 0-10v analog voltage output to control VFD speed adjustment 6.1 line normal open E-stop signal output7.Low power consumption design ,2pcs AA batteries can use 1 month in normal

- 200M barrier free transmission

- Support 4lines 250v/3A relay output

- Easy to use

-

Model: WHB04B-4 4 Axis WHB04B-6 6 Axis Application software: MACH3 Application Control card application industry :CNC cutting machine. CNC router.Machining Center.Mechanical arm.Automated production equipment 1.Radio Frequency: 433MHZ,ISM,TX power 10DB,RX sensitivity -98DB 2.100pulse per round MPG, support 10 customs key buttons 3.LCD monitor will display X/Y/Z/A/B/C mechanical and workpiece coordinates, support 3 axis coordinates display in one time RF support 64 channels, Each channel gap 1Mhz 4. Support Frequency hopping transmission, Stable and reliable 5.One room can run 64pcs MPG at the same time, and will not affect each other due to frequency hopping function 6.100PPR MPG function, customs macro function keys up to 10pcs

Model: WHB04B-4 4 Axis WHB04B-6 6 Axis Application software: MACH3 Application Control card application industry :CNC cutting machine. CNC router.Machining Center.Mechanical arm.Automated production equipment 1.Radio Frequency: 433MHZ,ISM,TX power 10DB,RX sensitivity -98DB 2.100pulse per round MPG, support 10 customs key buttons 3.LCD monitor will display X/Y/Z/A/B/C mechanical and workpiece coordinates, support 3 axis coordinates display in one time RF support 64 channels, Each channel gap 1Mhz 4. Support Frequency hopping transmission, Stable and reliable 5.One room can run 64pcs MPG at the same time, and will not affect each other due to frequency hopping function 6.100PPR MPG function, customs macro function keys up to 10pcsLCD mon itor display:Spindle speed value, processing feed rate value

- Support MACH3 system

- support 10 customs key buttons

- Wireless distance of 40 meters

-

Applicable to Siemens, Mitsubishi, FANUC, FAGOR, NUM, Taiwan Baoyuan, SYNTEC and other systems.

Applicable to Siemens, Mitsubishi, FANUC, FAGOR, NUM, Taiwan Baoyuan, SYNTEC and other systems. -

operating System Microsoft Windows7 Operating System CPU model Intel J1900 Hard disk 64G RAM 4G GPU Integrated LCD Display 15inches Resistive touch screen Port 8xUSB and 1xEthernet Power Supply DC24V/5A

- LCD Display

- Integrated system

-

Support system: SIEMENS,MITSUBISHI,FANUC,FAGOR,FRANCE NUM,TAIWAN BAOYUAN,XINDAI and so on. The Manual For Fully functionl Wireless Handle for Engraving machine: Typical applications: A variety of CNC machine tools: Machining center,cnc, Vertical lathe, Longmen milling machine Longmen engraving and milling machine.

Support system: SIEMENS,MITSUBISHI,FANUC,FAGOR,FRANCE NUM,TAIWAN BAOYUAN,XINDAI and so on. The Manual For Fully functionl Wireless Handle for Engraving machine: Typical applications: A variety of CNC machine tools: Machining center,cnc, Vertical lathe, Longmen milling machine Longmen engraving and milling machine.- 40m barrier-free distance

- Signal stabilization、strong anti-interference

- Easy to use

-

- E-stop button 6 custom buttons

- Anti-interference design, stable and reliable

- Wireless distance of 40 meters

-

-500x650.png)

CNC wireless handwheel Manual Pulse Generator For Mitsubishi

CNC wireless handwheel Manual Pulse Generator For Mitsubishi- 60m barrier-free distance

- Signal stabilization,strong anti-interference

- Easy to use

-

CNC wireless mpg Manual Pulse Generator For Mitsubishi Ab Phase 25ppr

CNC wireless mpg Manual Pulse Generator For Mitsubishi Ab Phase 25ppr- 60m barrier-free distance

- Signal stabilization、strong anti-interference

- Easy to use

-

Application:Specially used for crawler wire saw machine

1.Supports automatic cutting mode, automatically adjusts the walking speed of the small motor according to the large motor current, and achieves automatic cutting control. 2.Barrier-free transmission distance is 200 meters. 3. Supports dual speed regulation for large motors and small motors. 4. Support small motor turning in place. 5. Supports left and right wheel small motor linear correction.- Low power consumption design

- Easy to use

-

Enhanced type wireless MPG - ATWGP-12 axis

Enhanced type wireless MPG - ATWGP-12 axis- 40m barrier-free distance

- Signal stabilization、strong anti-interference

- Easy to use

-

Enhanced type wireless MPG - ATWGP-8/9/10 axis

Enhanced type wireless MPG - ATWGP-8/9/10 axis- 40m barrier-free distance

- Signal stabilization、strong anti-interference

- Easy to use

-

Applicable to Siemens, Mitsubishi, FANUC, FAGOR, NUM, Taiwan Baoyuan, SYNTEC and other systems. For large milling machines, CNC lathes, walking machine tools, cutting and other applications, it brings great convenience and improves work efficiency

Applicable to Siemens, Mitsubishi, FANUC, FAGOR, NUM, Taiwan Baoyuan, SYNTEC and other systems. For large milling machines, CNC lathes, walking machine tools, cutting and other applications, it brings great convenience and improves work efficiency -

Applicable to Siemens, Mitsubishi, FANUC, FAGOR, NUM, Taiwan Baoyuan, SYNTEC and other systems. Working principle: Using wireless transmission technology, the operation is more convenient,the traditional spring wire connection is omitted, the cable failure rate is reduced, and the inconveniences such as cable dragging and oil stain are avoided.

Applicable to Siemens, Mitsubishi, FANUC, FAGOR, NUM, Taiwan Baoyuan, SYNTEC and other systems. Working principle: Using wireless transmission technology, the operation is more convenient,the traditional spring wire connection is omitted, the cable failure rate is reduced, and the inconveniences such as cable dragging and oil stain are avoided. -

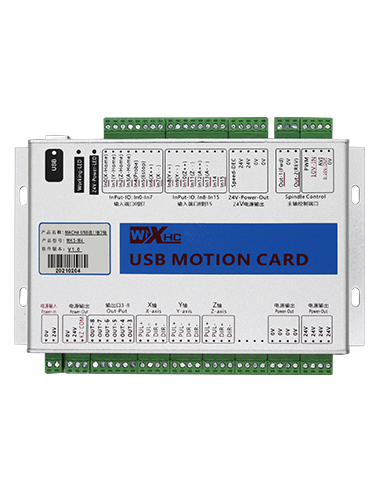

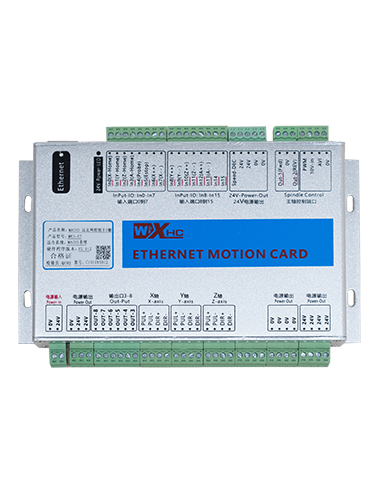

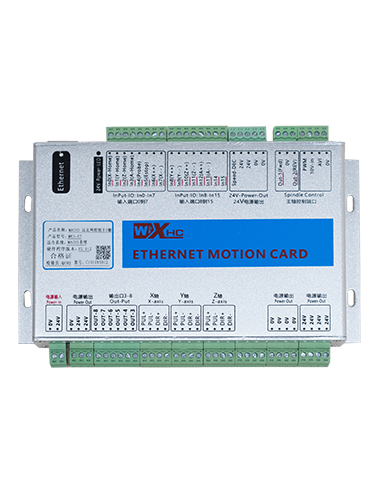

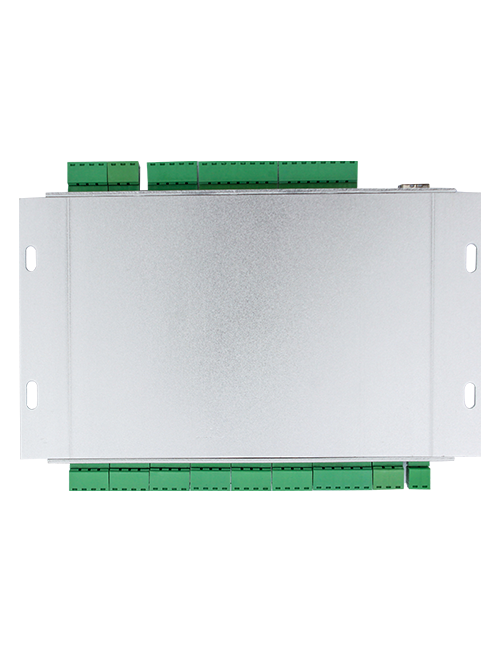

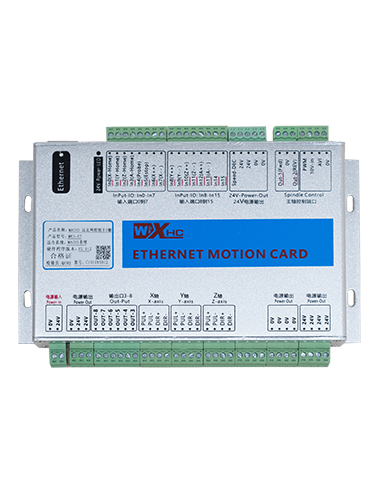

Model: MK3-ET 3AXIS MK4-ET 4AXIS MK6-ET 6AXIS Application software: MACH3 Application Control card application industry :CNC cutting machine. CNC router.Machining Center.Mechanical arm.Automated production equipment. Features: 1.Fully supporting all Mach3 versions 2.Full support for USB hot-swappable, the card is Monitoring USB connection status at any time. 3.Supports MAX 6-axis 4.Maximum step-pulse frequency is 2000KHz 5. Status indicator LED can be useful to show the USB connection, and working stauts by flashing. 6.16 input IO+8output IO, support spindle feedbackfunction, support difference output. all IO-port isolation, interference, stable performance

Model: MK3-ET 3AXIS MK4-ET 4AXIS MK6-ET 6AXIS Application software: MACH3 Application Control card application industry :CNC cutting machine. CNC router.Machining Center.Mechanical arm.Automated production equipment. Features: 1.Fully supporting all Mach3 versions 2.Full support for USB hot-swappable, the card is Monitoring USB connection status at any time. 3.Supports MAX 6-axis 4.Maximum step-pulse frequency is 2000KHz 5. Status indicator LED can be useful to show the USB connection, and working stauts by flashing. 6.16 input IO+8output IO, support spindle feedbackfunction, support difference output. all IO-port isolation, interference, stable performance- MACH3 system

- Supports MAX 6-axis

- Maximum step-pulse frequency is 2000KHz

-

Model: MK3-ET 3AXIS MK4-ET 4AXIS MK6-ET 6AXIS Application software: MACH3 Application Control card application industry :CNC cutting machine. CNC router.Machining Center.Mechanical arm.Automated production equipment. Features: 1.Fully supporting all Mach3 versions 2.Full support for USB hot-swappable, the card is Monitoring USB connection status at any time. 3.Supports MAX 6-axis 4.Maximum step-pulse frequency is 2000KHz 5. Status indicator LED can be useful to show the USB connection, and working stauts by flashing. 6.16 input IO+8output IO, support spindle feedbackfunction, support difference output. all IO-port isolation, interference, stable performance

Model: MK3-ET 3AXIS MK4-ET 4AXIS MK6-ET 6AXIS Application software: MACH3 Application Control card application industry :CNC cutting machine. CNC router.Machining Center.Mechanical arm.Automated production equipment. Features: 1.Fully supporting all Mach3 versions 2.Full support for USB hot-swappable, the card is Monitoring USB connection status at any time. 3.Supports MAX 6-axis 4.Maximum step-pulse frequency is 2000KHz 5. Status indicator LED can be useful to show the USB connection, and working stauts by flashing. 6.16 input IO+8output IO, support spindle feedbackfunction, support difference output. all IO-port isolation, interference, stable performance- MACH3 system

- Supports MAX 6-axis

- Maximum step-pulse frequency is 2000KHz

-

Model: MK3-ET 3AXIS MK4-ET 4AXIS MK6-ET 6AXIS Application software: MACH3 Application Control card application industry :CNC cutting machine. CNC router.Machining Center.Mechanical arm.Automated production equipment. Features: 1.Fully supporting all Mach3 versions 2.Full support for USB hot-swappable, the card is Monitoring USB connection status at any time. 3.Supports MAX 6-axis 4.Maximum step-pulse frequency is 2000KHz 5. Status indicator LED can be useful to show the USB connection, and working stauts by flashing. 6.16 input IO+8output IO, support spindle feedbackfunction, support difference output. all IO-port isolation, interference, stable performance

Model: MK3-ET 3AXIS MK4-ET 4AXIS MK6-ET 6AXIS Application software: MACH3 Application Control card application industry :CNC cutting machine. CNC router.Machining Center.Mechanical arm.Automated production equipment. Features: 1.Fully supporting all Mach3 versions 2.Full support for USB hot-swappable, the card is Monitoring USB connection status at any time. 3.Supports MAX 6-axis 4.Maximum step-pulse frequency is 2000KHz 5. Status indicator LED can be useful to show the USB connection, and working stauts by flashing. 6.16 input IO+8output IO, support spindle feedbackfunction, support difference output. all IO-port isolation, interference, stable performance- MACH3 system

- Supports MAX 6-axis

- Maximum step-pulse frequency is 2000KHz

-

Application:Specially used for floor grinder automation wireless control

1.Using frequency hopping transmission technology and 32 sets of equipment can be used at the same time on the spot without interfering with each other. 2.Barrier-free transmission distance is 200 meters. 3. Support 2 channel analog: 0-10V analog voltage output. 4. Support 7-way switching relay output, with load capacity: AC 3A/250V or DC 5A/30V. 5. Support 1 channel emergency stop output, load capacity AC 3A/250V or DC 5A/30V. 6. LCD display with backlight, displaying 2 outputs and 7 switching statuses.- Low power consumption design

- Easy to use

-

Application:Welding machine automation welding and welding operator.Turn Rolls

1.Use 433MHZ wireless transmission frequency .long distance wireless frequency hopping technology .wireless control distance 200m without barrier

2.In the same working area,it can support 32pcs equipments used at the same time 3.LCD monitor can display present welding current ,voltage and speed 4.Support 4lines 250v/3A relay output.to control contactor achieve motor clock wise/counter-clock wise 5.Support 1lines 0-10v analog voltage output to control VFD speed adjustment 6.1 line normal open E-stop signal output 7.Low power consumption design ,2pcs AA batteries can use 1 month in normal- 200M barrier free transmission

- Low power consumption design

- Easy to use

-

-500x650.png)

Application:Welding machine automation welding and welding operator.Turn Rolls

1.Use 433MHZ wireless transmission frequency .long distance wireless frequency hopping technology .wireless control distance 200m without barrier

2.In the same working area,it can support 32pcs equipments used at the same time 3.LCD monitor can display present welding current ,voltage and speed 4.Support 4lines 250v/3A relay output.to control contactor achieve motor clock wise/counter-clock wise 5.Support 1lines 0-10v analog voltage output to control VFD speed adjustment 6.1 line normal open E-stop signal output 7.Low power consumption design ,2pcs AA batteries can use 1 month in normal- 200M barrier free transmission

- Low power consumption design

- Easy to use

-

Application:Welding machine automation welding and welding operator.Turn Rolls

1.Use 433MHZ wireless transmission frequency .long distance wireless frequency hopping technology .wireless control distance 200m without barrier

2.In the same working area,it can support 32pcs equipments used at the same time 3.LCD monitor can display present welding current ,voltage and speed 4.Support 4lines 250v/3A relay output.to control contactor achieve motor clock wise/counter-clock wise 5.Support 1lines 0-10v analog voltage output to control VFD speed adjustment 6.1 line normal open E-stop signal output 7.Low power consumption design ,2pcs AA batteries can use 1 month in normal- 200M barrier free transmission

- Low power consumption design

- Easy to use

-

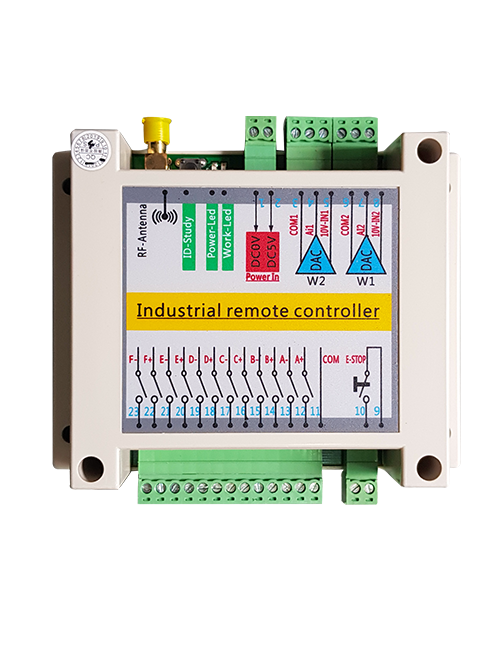

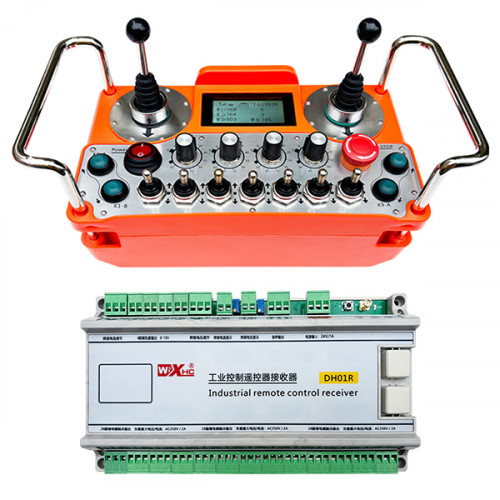

Application:used for various industrial equipment

1.Maximum 26 relay outputs. 2.Barrier-free transmission distance is 200 meters. 3. Maximum 4 channels of analog 0-10V output (display range can be customized): supports 2 channels of extended isolated digital potentiometer output; 4. 2 analog inputs; and displayed on the remote control, the display range can be customized. 5. 1 emergency stop relay output normally closed contact.- Low power consumption design

- Easy to use

-

Application:Welding machine automation welding and welding operator.Turn Rolls

1.Use 433MHZ wireless transmission frequency .long distance wireless frequency hopping technology .wireless control distance 200m without barrier 2.In the same working area,it can support 32pcs equipments used at the same time 3.Digital tube display present welding current ,voltage and speed 4.Support 4lines 250v/3A relay output.to control contactor achieve motor clock wise/counter-clock wise 5.Support 1lines 0-10v analog voltage output to control VFD speed adjustment 6.1 line normal open E-stop signal output7.Low power consumption design ,2pcs AA batteries can use 1 month in normal

- 200M barrier free transmission

- Digital tube display

- Easy to use

-

Application:Welding machine automation welding and welding operator.Turn Rolls

1.Use 433MHZ wireless transmission frequency .long distance wireless frequency hopping technology .wireless control distance 200m without barrier

2.In the same working area,it can support 32pcs equipments used at the same time 3.LCD monitor can display present welding current ,voltage and speed 4.Support 4lines 250v/3A relay output.to control contactor achieve motor clock wise/counter-clock wise 5.Support 1lines 0-10v analog voltage output to control VFD speed adjustment 6.1 line normal open E-stop signal output 7.Low power consumption design ,2pcs AA batteries can use 1 month in normal- 200M barrier free transmission

- Low power consumption design

- Easy to use

-

Features: 1. The main motor cutting current can be set 2. Automatic control of cutting speed 3. Automatically detect cutting materials to realize unmanned duty 4. Simple and easy to use 5. With retracting function 6. With main motor protection function

- 200M barrier free transmission

- Low power consumption design

- Easy to use

-

Features: 1. The main motor cutting current can be set 2. Automatic control of cutting speed 3. Automatically detect cutting materials to realize unmanned duty 4. Simple and easy to use 5. With retracting function 6. With main motor protection function

- 200M barrier free transmission

- Low power consumption design

- Easy to use

-

Application:Welding machine automation welding and welding operator.Turn Rolls

1.Use 433MHZ wireless transmission frequency .long distance wireless frequency hopping technology .wireless control distance 200m without barrier

2.In the same working area,it can support 32pcs equipments used at the same time 3.LCD monitor can display present welding current ,voltage and speed 4.Support 4lines 250v/3A relay output.to control contactor achieve motor clock wise/counter-clock wise 5.Support 1lines 0-10v analog voltage output to control VFD speed adjustment 6.1 line normal open E-stop signal output 7.Low power consumption design ,2pcs AA batteries can use 1 month in normal- 200M barrier free transmission

- Low power consumption design

- Easy to use

-

Application:Welding machine automation welding and welding operator.Turn Rolls

1.Use 433MHZ wireless transmission frequency .long distance wireless frequency hopping technology .wireless control distance 200m without barrier

2.In the same working area,it can support 32pcs equipments used at the same time 3.LCD monitor can display present welding current ,voltage and speed 4.Support 4lines 250v/3A relay output.to control contactor achieve motor clock wise/counter-clock wise 5.Support 1lines 0-10v analog voltage output to control VFD speed adjustment 6.1 line normal open E-stop signal output 7.Low power consumption design ,2pcs AA batteries can use 1 month in normal- 200M barrier free transmission

- Low power consumption design

- Easy to use

-

Application:Welding machine automation welding and welding operator.Turn Rolls

1.Using frequency hopping transmission technology, the wireless performance is stable and reliable.

2.In the same working area,it can support 32pcs equipments used at the same time.

3.Support 4 channels of analog, 0-10V analog voltage input. 4.Support 18 relay outputs, with load capacity: AC 3A/250V or DC 5A/30V 5.LCD display with backlight, display W1-W4 output and input,always with 18 switches 6.Low power consumption design ,2pcs AA batteries can use 1 month in normal- Low power consumption design

- Easy to use

-

Application:Welding machine automation welding and welding operator.Turn Rolls

1.Use 433MHZ wireless transmission frequency .long distance wireless frequency hopping technology .wireless control distance 200m without barrier 2.In the same working area,it can support 32pcs equipments used at the same time 3.LCD monitor can display present welding current ,voltage and speed 4.Support 4lines 250v/3A relay output.to control contactor achieve motor clock wise/counter-clock wise 5.Support 1lines 0-10v analog voltage output to control VFD speed adjustment 6.1 line normal open E-stop signal output7.Low power consumption design ,2pcs AA batteries can use 1 month in normal

- 200M barrier free transmission

- Support 4lines 250v/3A relay output

- Easy to use

-

Product advantages: Industrial grade computer configuration Support VGA interface Support 6 USB ports Pre-installed WIN8 embedded, directly plugging in the power supply does not affect Hard disk memory 32G Input IO port: 24 Output IO port: 16 Support single card configuration or dual card configuration at will

- MACH3 software

- Supports MAX 6-axis

- Integrated system

-

operating System Microsoft Windows10 Operating System Numerical control software Mach3 CNC software CPU model Intel Z3735F Hard disk 8G + 20G SSD Memory 2G Graphics integrated graphics The display is 10.0 inches Communication port 3 USB 2.0 ports, one Ethernet port Input device keyboard + touch mouse + MPG control keyboard Power supply three plug type, 220V Fourth, the packaging instructions Mach3 one machine 1 set Mach3 one machine manual 1 this Power cord 1 root

include the computer and mach3 software only- MACH3 software

- Supports MAX 6-axis

- Integrated system

-

Features: 1.Fully supporting all Mach3 versions 2.Full support for USB hot-swappable, the card is Monitoring USB connection status at any time. 3.Supports MAX 6-axis 4.Maximum step-pulse frequency is 2000KHz 5. Status indicator LED can be useful to show the USB connection, and working stauts by flashing. 6.16 input IO+8output IO, support spindle feedbackfunction, support difference output. all IO-port isolation, interference,

Features: 1.Fully supporting all Mach3 versions 2.Full support for USB hot-swappable, the card is Monitoring USB connection status at any time. 3.Supports MAX 6-axis 4.Maximum step-pulse frequency is 2000KHz 5. Status indicator LED can be useful to show the USB connection, and working stauts by flashing. 6.16 input IO+8output IO, support spindle feedbackfunction, support difference output. all IO-port isolation, interference,stable performance

- MACH3 system

- Supports MAX 6-axis

- Maximum step-pulse frequency is 2000KHz