- 40m barrier-free distance

- Low power design

- -98dB detonator sensitivity

-

XHC one year warranty Siemens cnc pendant mpg handwheel Support system: SIEMENS,MITSUBISHI,FANUC,FAGOR,FRANCE NUM,TAIWAI BAOYUAN,XINDAI and so on. Wireless electronic manual pulse generator wireless ISM band 433MHz 1ODB transmit power, -98dB detonator sensitivity, isolation distance 50m The anti-interference design is stable and reliable, and the use of 32 sets of wireless MPG in the room does not affect each other. Low power design, 2AA battery, normal use for more than 30 days With the function of axis selection, multiple selection function With LCD display zero, sub function, LCD can display X, Y, Z, 4,5,6 axis increment sitting value (no LCD display type does not take this function). The alloy encoders have stable and reliable performance, good handle and clear tooth position. The buttons are waterproof switch and can be used.

XHC one year warranty Siemens cnc pendant mpg handwheel Support system: SIEMENS,MITSUBISHI,FANUC,FAGOR,FRANCE NUM,TAIWAI BAOYUAN,XINDAI and so on. Wireless electronic manual pulse generator wireless ISM band 433MHz 1ODB transmit power, -98dB detonator sensitivity, isolation distance 50m The anti-interference design is stable and reliable, and the use of 32 sets of wireless MPG in the room does not affect each other. Low power design, 2AA battery, normal use for more than 30 days With the function of axis selection, multiple selection function With LCD display zero, sub function, LCD can display X, Y, Z, 4,5,6 axis increment sitting value (no LCD display type does not take this function). The alloy encoders have stable and reliable performance, good handle and clear tooth position. The buttons are waterproof switch and can be used. -

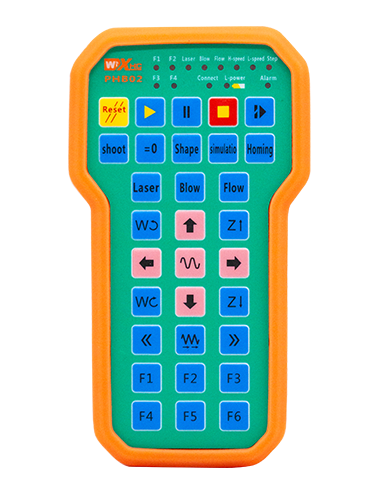

- Support NC studio system

- support 10 customs key buttons

- Wireless distance of 40 meters

-

XHC wireless MPG AWGP for CNC center

XHC wireless MPG AWGP for CNC center- 40m barrier-free distance

- Signal stabilization、strong anti-interference

- Easy to use

-

1. Provide DLL library file for Windows 2. Provide VC example programs for electronic handwheel applications, including VC source code 3.USB interface, adopt USB1.1 full speed transmission 4. Customer secondary development 5. Provide 128 * 64 dot matrix LCD display, customers can download the display content through DLL 6. Provides 31 key inputs 7. Provide 100PPR electronic handwheel input 8. Barrier-free operating distance: 40 m 9. Patented XHC wireless transmission protocol; automatic frequency hopping, strong anti-interference ability 10. Low power consumption design: 2 AA batteries, use time 30 days 11.32 sets of equipment, simultaneous use does not affect 12. Industrial-grade design, dust-proof design, stable and reliable.

- Provide DLL library file for Windows

- Provide VC example programs for electronic handwheel applications, including VC source code

- Secondary development

-

Support system: SIEMENS,MITSUBISHI,FANUC,FAGOR,FRANCE NUM,TAIWAN BAOYUAN,XINDAI and so on. The Manual For Fully functionl Wireless Handle for Engraving machine: Typical applications: A variety of CNC machine tools: Machining center,cnc, Vertical lathe, Longmen milling machine Longmen engraving and milling machine.

Support system: SIEMENS,MITSUBISHI,FANUC,FAGOR,FRANCE NUM,TAIWAN BAOYUAN,XINDAI and so on. The Manual For Fully functionl Wireless Handle for Engraving machine: Typical applications: A variety of CNC machine tools: Machining center,cnc, Vertical lathe, Longmen milling machine Longmen engraving and milling machine.- 40m barrier-free distance

- Signal stabilization、strong anti-interference

- Easy to use

-

Application:Specially used for crawler wire saw machine

1.Supports automatic cutting function, automatically adjusts cutting speed according to motor current feedback 2.Barrier-free transmission distance is 200 meters. 3. Support DC driver. 4. Supports multiple cutting parameter settings, such as cutting current, cutting speed limit, etc. 5. Supports switching between wire saw and blade saw modes. Different cutting parameters can be set in different modes.- Low power consumption design

- Easy to use

-

25 switch quantities, 4 analog quantities, buttons can be used for subtraction, panels can be customized, used in electric welding machines, roller frames, wire saw cutting and other industries Using 433 communication protocol and remote wireless frequency hopping transmission, the wireless remote control of electric welding machine is realized. Application:electric welding turning rolls 1.433 wireless transmission protocol, long distance wireless frequency hopping, 200M barrier free transmission 2.Support 32 sets of equipment at the same place at the same time 3.Display welding current, welding voltage and welding speed 4. Two roads of 5K isolation digital potentiometer output, realize welding current and voltage remote control 5. Two 10V analog voltage output, control converter speed regulation. 6.25 way 250V/3A relay output, control contactor 7.Emergency stop relay output

25 switch quantities, 4 analog quantities, buttons can be used for subtraction, panels can be customized, used in electric welding machines, roller frames, wire saw cutting and other industries Using 433 communication protocol and remote wireless frequency hopping transmission, the wireless remote control of electric welding machine is realized. Application:electric welding turning rolls 1.433 wireless transmission protocol, long distance wireless frequency hopping, 200M barrier free transmission 2.Support 32 sets of equipment at the same place at the same time 3.Display welding current, welding voltage and welding speed 4. Two roads of 5K isolation digital potentiometer output, realize welding current and voltage remote control 5. Two 10V analog voltage output, control converter speed regulation. 6.25 way 250V/3A relay output, control contactor 7.Emergency stop relay output8.Low power design, only 3 AA batteries for a month

- 200M barrier free transmission

- 25 way 250V/3A relay output, control contactor

- Easy to use

-

25 switch quantities, 4 analog quantities, buttons can be used for subtraction, panels can be customized, used in electric welding machines, roller frames, wire saw cutting and other industries Using 433 communication protocol and remote wireless frequency hopping transmission, the wireless remote control of electric welding machine is realized. Application:electric welding turning rolls 1.433 wireless transmission protocol, long distance wireless frequency hopping, 200M barrier free transmission 2.Support 32 sets of equipment at the same place at the same time 3.Display welding current, welding voltage and welding speed 4. Two roads of 5K isolation digital potentiometer output, realize welding current and voltage remote control 5. Two 10V analog voltage output, control converter speed regulation. 6.25 way 250V/3A relay output, control contactor 7.Emergency stop relay output

25 switch quantities, 4 analog quantities, buttons can be used for subtraction, panels can be customized, used in electric welding machines, roller frames, wire saw cutting and other industries Using 433 communication protocol and remote wireless frequency hopping transmission, the wireless remote control of electric welding machine is realized. Application:electric welding turning rolls 1.433 wireless transmission protocol, long distance wireless frequency hopping, 200M barrier free transmission 2.Support 32 sets of equipment at the same place at the same time 3.Display welding current, welding voltage and welding speed 4. Two roads of 5K isolation digital potentiometer output, realize welding current and voltage remote control 5. Two 10V analog voltage output, control converter speed regulation. 6.25 way 250V/3A relay output, control contactor 7.Emergency stop relay output8.Low power design, only 3 AA batteries for a month

- 200M barrier free transmission

- 25 way 250V/3A relay output, control contactor

- Easy to use

-

Support Siemens PLC: S7-200/-300/-1200

Support real-time display of Siemens system coordinate values

6 custom buttons can control 6 switch outputs

- The wireless transmission distance is open 40 meter

- support:one 100PPR encoder 、one 6-speed axis selection switch 、 one 3-speed magnification switch

-

1. Provide DLL library file for Windows 2. Provide VC example programs for electronic handwheel applications, including VC source code 3.USB interface, adopt USB1.1 full speed transmission 4. Customer secondary development 5. Provide 128 * 64 dot matrix LCD display, customers can download the display content through DLL 6. Provides 31 key inputs 7. Provide 100PPR electronic handwheel input 8. Barrier-free operating distance: 40 m 9. Patented XHC wireless transmission protocol; automatic frequency hopping, strong anti-interference ability 10. Low power consumption design: 2 AA batteries, use time 30 days 11.32 sets of equipment, simultaneous use does not affect 12. Industrial-grade design, dust-proof design, stable and reliable.

- Provide DLL library file for Windows

- Provide VC example programs for electronic handwheel applications, including VC source code

- Secondary development

-

The remote controlsupports up to 32 custom buttons, corresponding to Siemens PLC addresses,which can be freely programmed; 9 LED status indicators, support Siemens PLC address, freely programmable;

The remote controlsupports up to 32 custom buttons, corresponding to Siemens PLC addresses,which can be freely programmed; 9 LED status indicators, support Siemens PLC address, freely programmable; -

Programmable CNC remote control is a kind of wireless equipment provided to developers for secondary development and remote control of CNC system through wireless remote control technology; We provide users with DLL Dynamic Link Library under Windows development environment, so that developers can use the remote control function for secondary development, and make it suitable for developers' own software system.

Programmable CNC remote control is a kind of wireless equipment provided to developers for secondary development and remote control of CNC system through wireless remote control technology; We provide users with DLL Dynamic Link Library under Windows development environment, so that developers can use the remote control function for secondary development, and make it suitable for developers' own software system.