Fakamatalá

1.Introduction of remote control

a.Product Composition

Siemens real-time coordinate display wireless electronic handwheel consists of two parts: electronic handwheel + receiver;

b.Characteristics

*Poupou ki he Siemens PLC: S7-200/-300/-1200;Poupouʻi ʻa e fakaʻaliʻali taimi moʻoni ʻo e ngaahi tuʻunga ʻulungaanga mahuʻinga ʻo e polokalama Siemens;

*ʻOku ava ʻa e mamaʻo ʻo e fetuʻutaki uaea 40 mita ʻe, automatic frequency hopping technology, can use 32 sets of equipment at the same time;

*The electronic handwheel is powered by 2 AA batteries and can be used for more than 30 ngaahi ʻahó;

*The receiver is equipped with an external antenna to enhance the signal and is easy to install;

*Electronic handwheel support: 100PPR encoder ʻe taha 、meʻa kamosi ʻe taha ʻo e 6-speed axis fili 、 meʻa kamosi fakalahi vave ʻe taha;

*Electronic handwheel supports 6 buttons ʻoku mou lava ʻo tānaki atu, corresponding to Siemens PLC address, ʻa ia ʻe lava pe ke fakapolokalamaʻi tauʻataina;

*6 ʻE lava ke mapuleʻi ʻa e ngaahi meʻa lomi 6 Liliu ʻa e output;

*The display screen displays the PLC corresponding register coordinate value in real time, and supports 6-axis display of real-time coordinates.

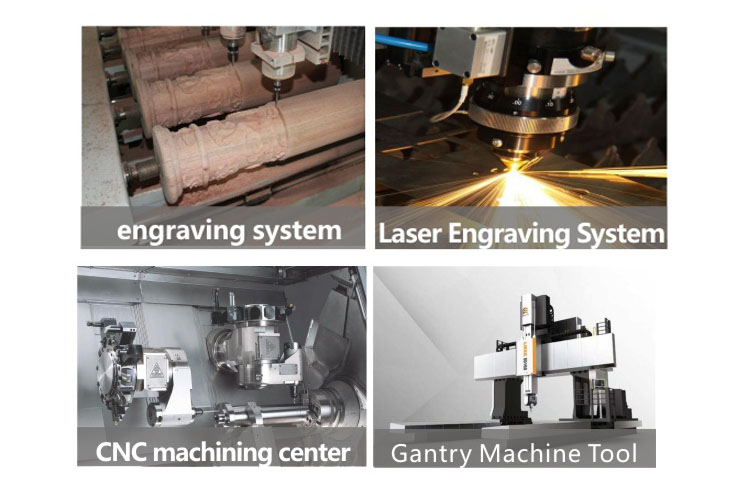

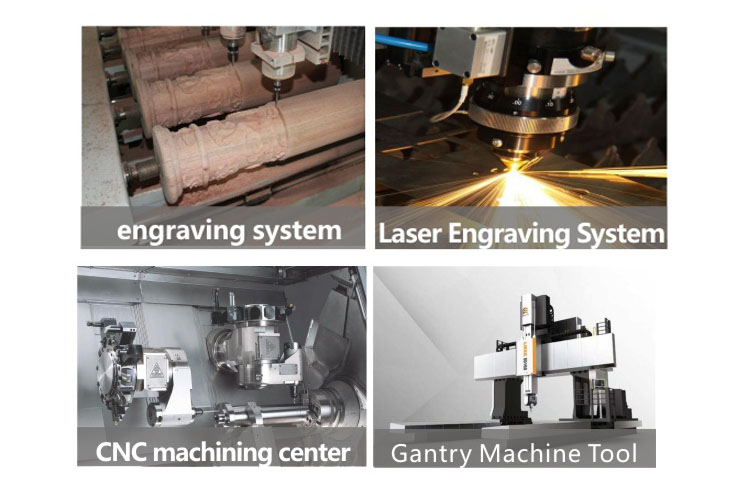

2.Application field

Programmable CNC remote control is widely used in various CNC fields such as laser engraving system, CNC milling misini, Senita CNC machining, gantry machine tool, ala meʻa pehe.

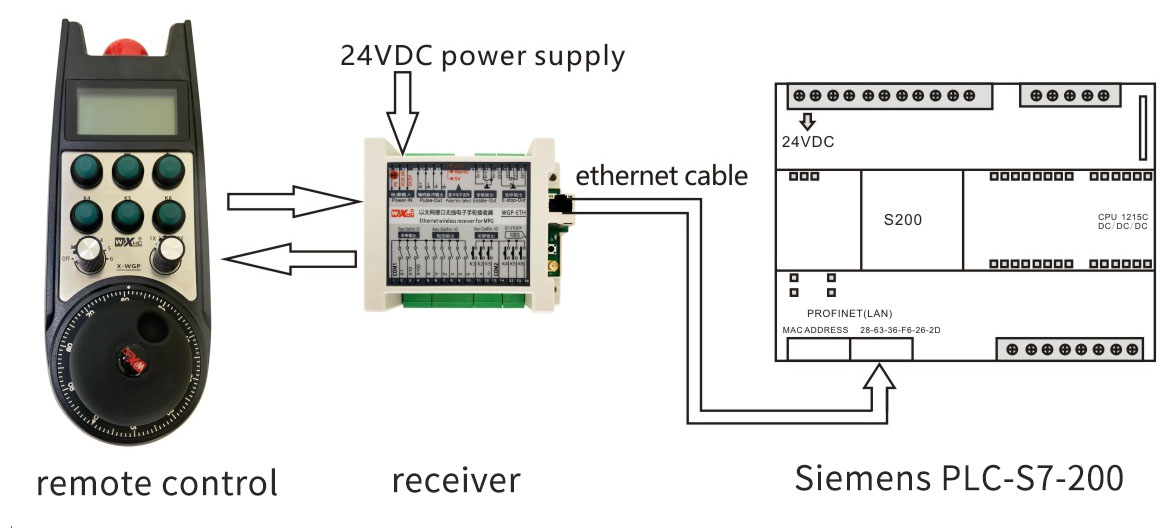

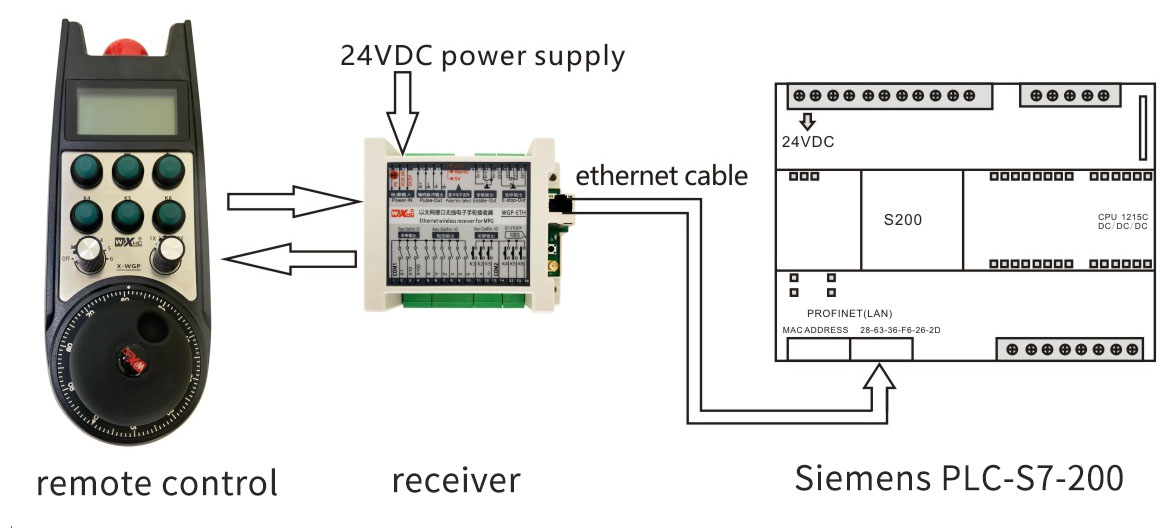

3. Introduction to the working principle

1)Electronic handwheel is connected to PLC via Ethernet receiver

a.The handwheel transmits the key data wirelessly to the receiver, and the receiver writes the keys through the network cable PLC system DB area; the receiver reads the data to be displayed from the designated DB area, and then returns the data to the handwheel display screen. The user can customize the base address of reading and writing DB area on the handwheel, so that the handwheel can read and write the data in the DB area of the PLC.

b. The receiver supports Siemens S7 protocol. Applies to PLC S7-200, PLC S7-300 and PLC S7-1200.

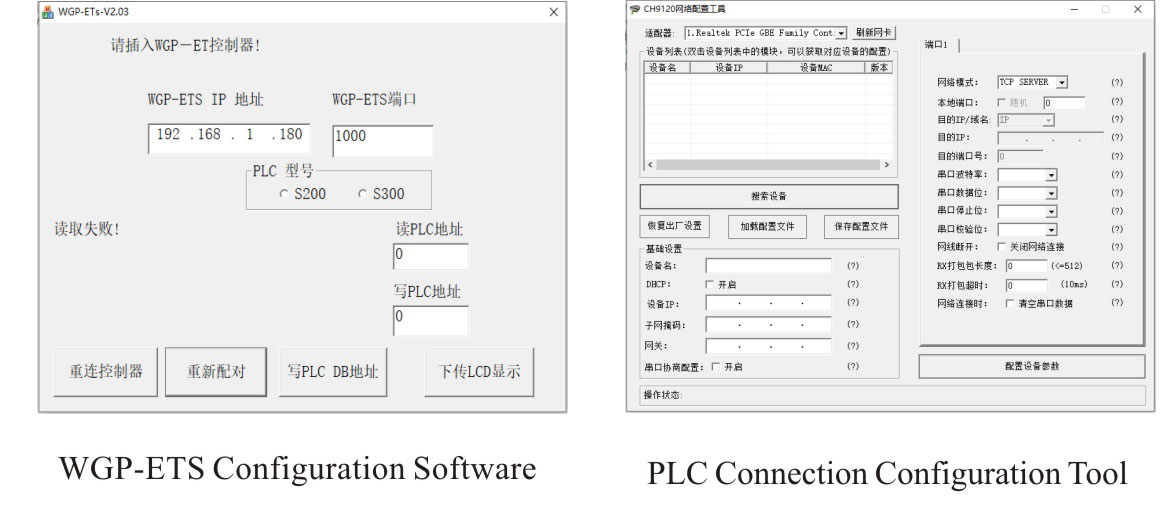

c. The user can configure the receiver to server mode and client mode through the PLC connection configuration tool.

In the server mode, the user configures the PLC read and write address through the WGP-ETS configuration software;Use the PLC connection configuration tool to configure the receiver into client mode. After configuration, the XWGP-ETS receiver can communicate with the PLC through the standard S7 protocol.

2)Specific application

Specific application of handwheel receiver and Siemens PLC S7-200:

a. The button on the handwheel corresponds to the value of the BOOL area set by the user in the PLC. If the button of the handwheel is pressed, the corresponding BOOL area is true, and when it is released, it is false, and the base address of the BOOL area can be set through the handwheel;

b. The handwheel can read the value of the DB area in the PLC. One axis has 4 bytes of display data, mo e 6 axes have a total of 24 bytes. The base address of the DB area can be set through the WGP-ETS configuration software.

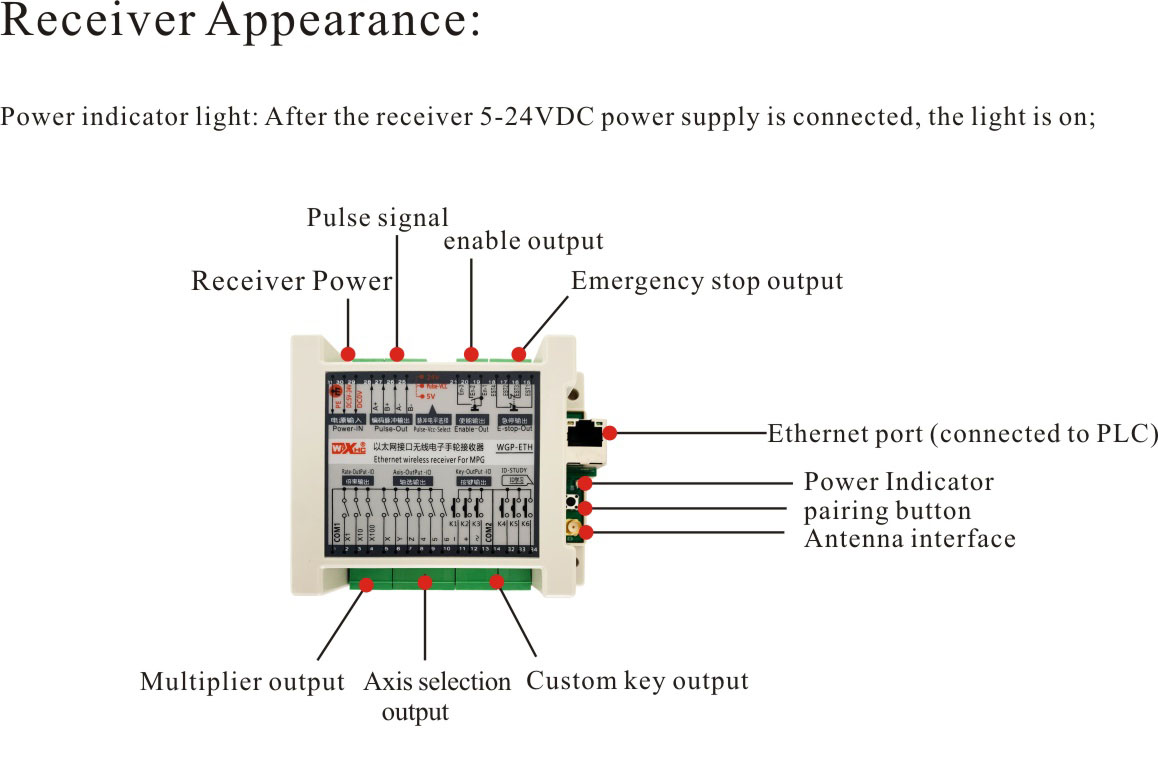

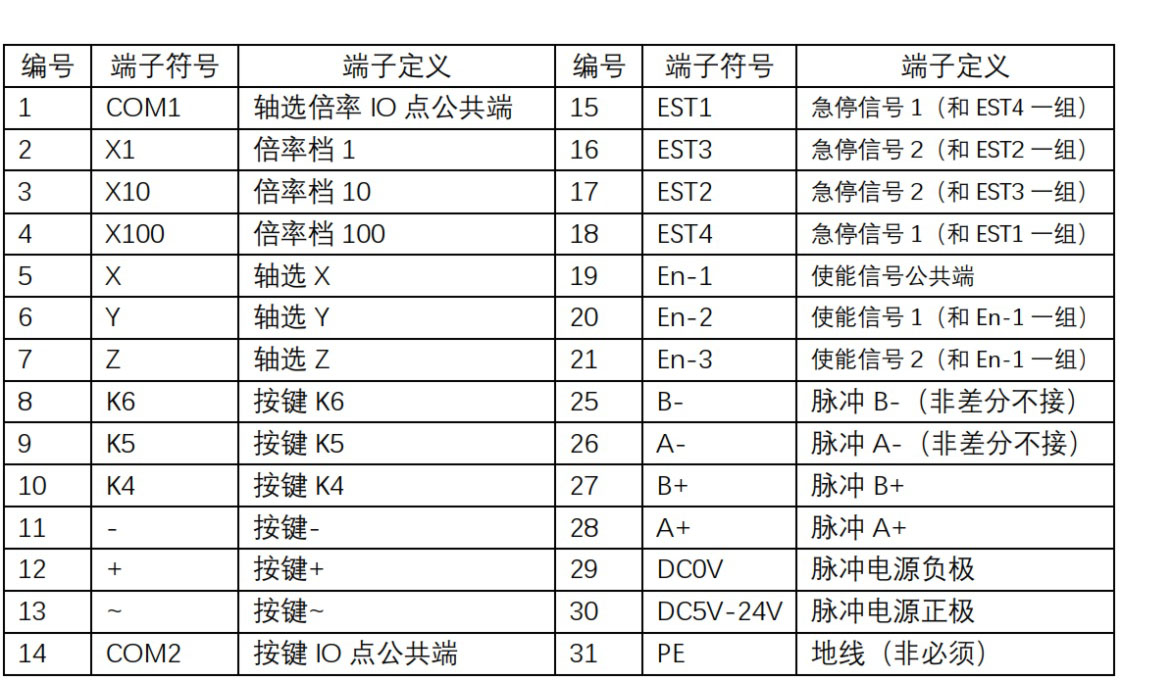

4.Appearance introduction

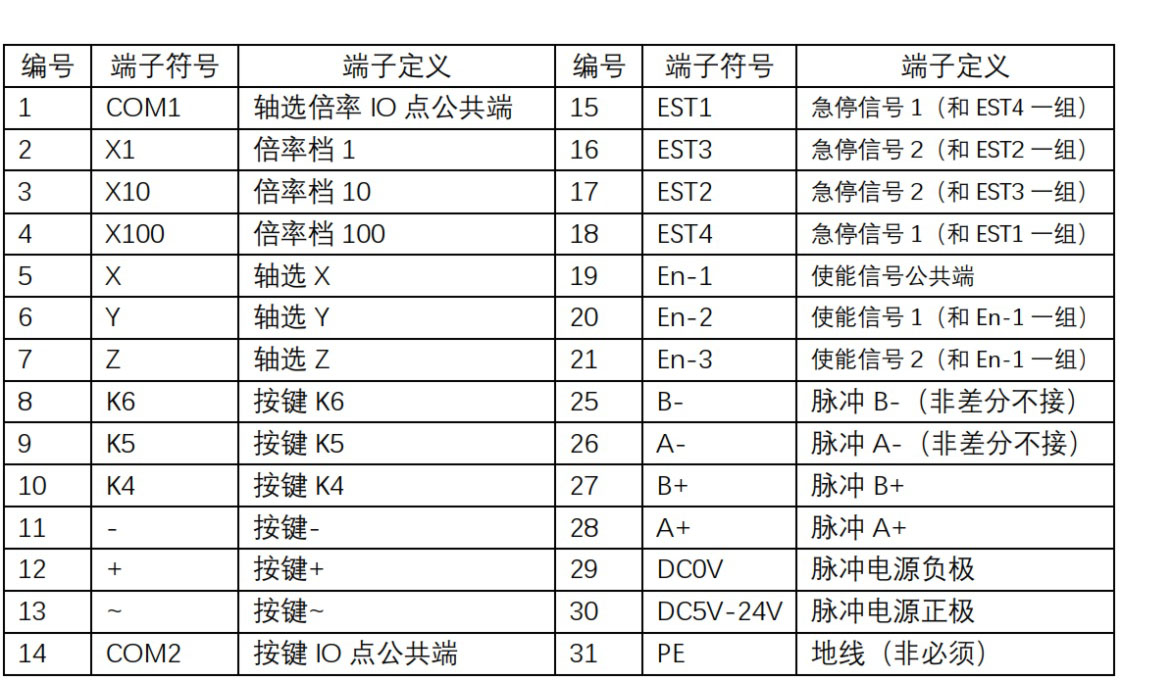

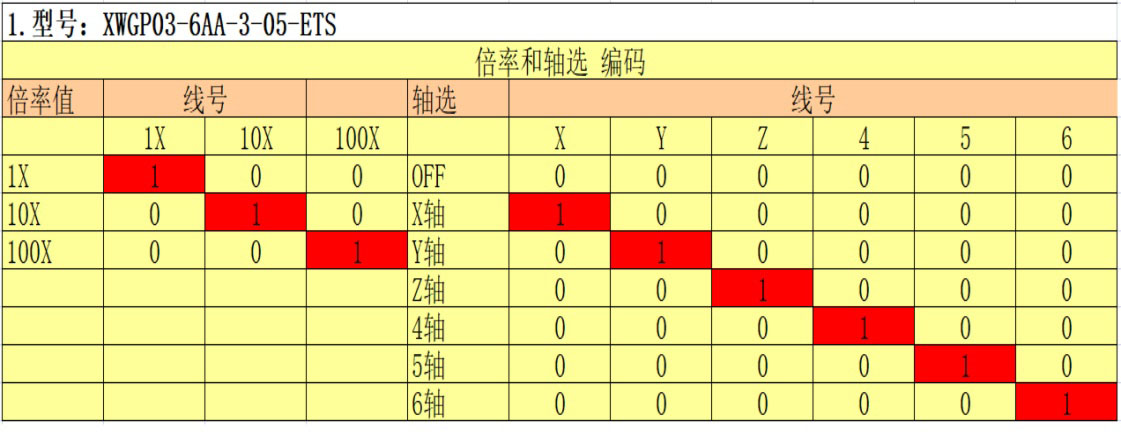

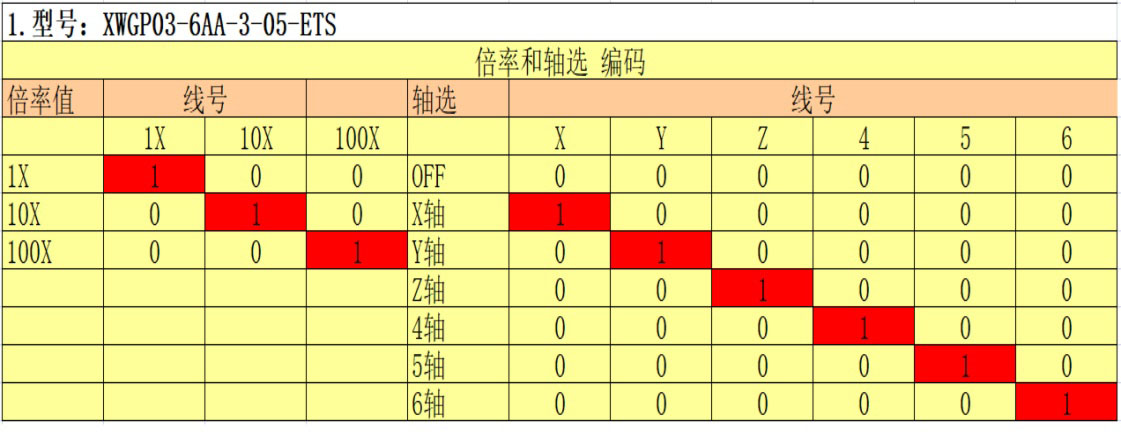

5.Receiver terminal definition and coding table

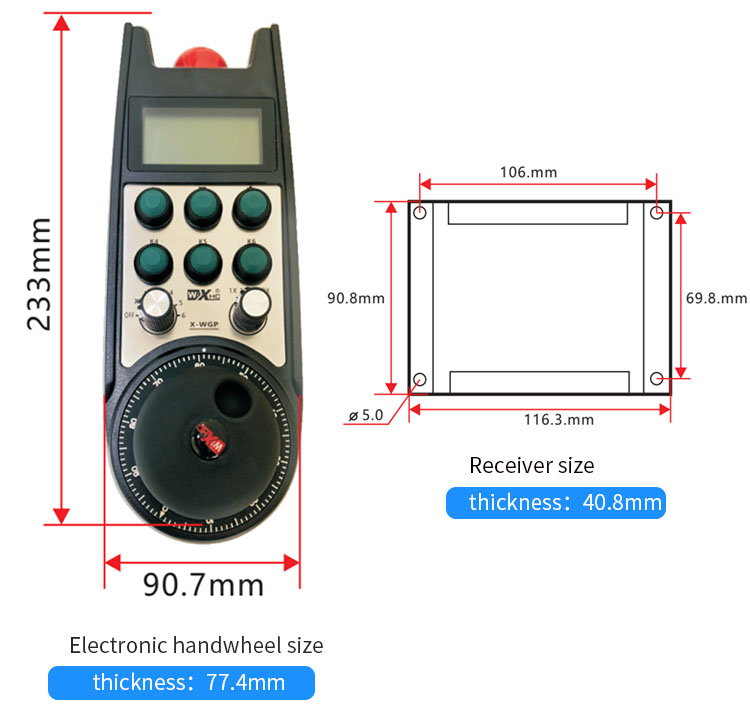

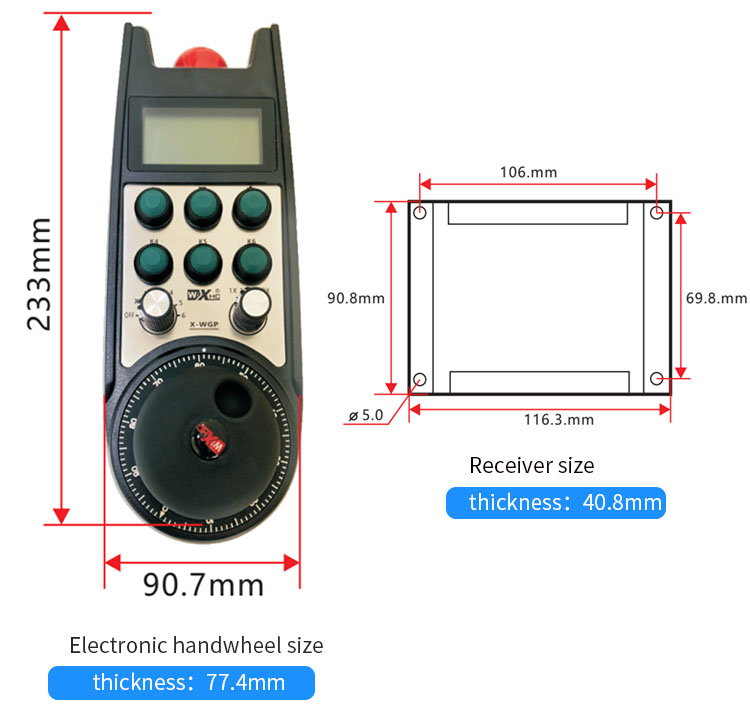

6.Appearance size