Tuairisgeul

1.Toirt a-steach smachd iomallach

A.prounted composag obair

Siemens Real-ùine co-òrdanachaidh Real-RIAGHALTAS DACHAIGH DÙTHCHAIL A 'GABHAIL A' GABHAIL A-STEACH DÀTA AIR DÀTA: Coilean-làimhe dealanach + Glacadair;

b.Carraracters

*Thoir taic do Siemens plc: S7-200 / -300 / -1200;Thoir taic do thaisbeanadh fìor-ùine de luachan co-òrdanachaidh Siostam Siemens;

*Tha an astar tar-chuir gun uèir fosgailte 40 meatairean, teicneòlas hopaidh fèin-ghluasadach fèin-ghluasadach, urrainn a chleachdadh 32 Seataichean uidheamachd aig an aon àm;

*Tha an ceadachd-làimhe dealanach air a chumhachdachadh le 2 Aa bataraidhean AA agus faodar a chleachdadh airson barrachd air 30 làithean;

*Tha an tecaris uidheamaichte le antenna a-muigh gus an comharra a neartachadh agus tha e furasta a stàladh;

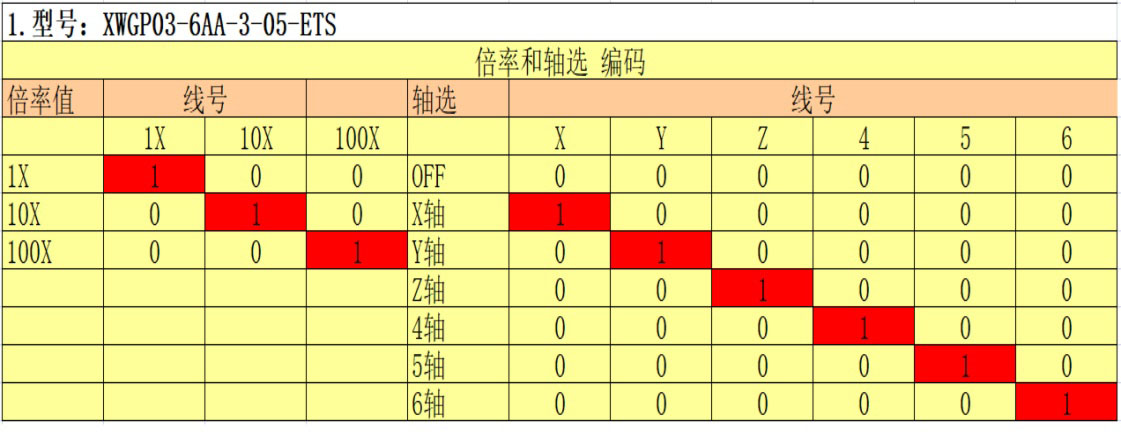

*Taic làimhe dealanach: aon neach-faighinn 100ppr 、aon tionndadh taghaidh Aonach 6-astar 、 aon tionndadh meudachd 3-astar;

*Tha taic-làimhe dealanach a 'toirt taic do 6 putanan gnàthaichte, A 'freagairt ri seòladh Plc Siemens Plc, a dh 'fhaodar a chlàradh gu saor;

*6 Faodaidh putanan gnàthaichte smachd a chumail air 6 Toirmeasg a-steach;

*Tha an scrion Taisbearaidh a 'taisbeanadh an clàr co-chòrdadh ri co-òrdanachaidh PLC le luach iomlan ann an àm fìor, agus a 'toirt taic do thaisbeanadh 6-Axis de cho-òrdanachadh fìor-ùine.

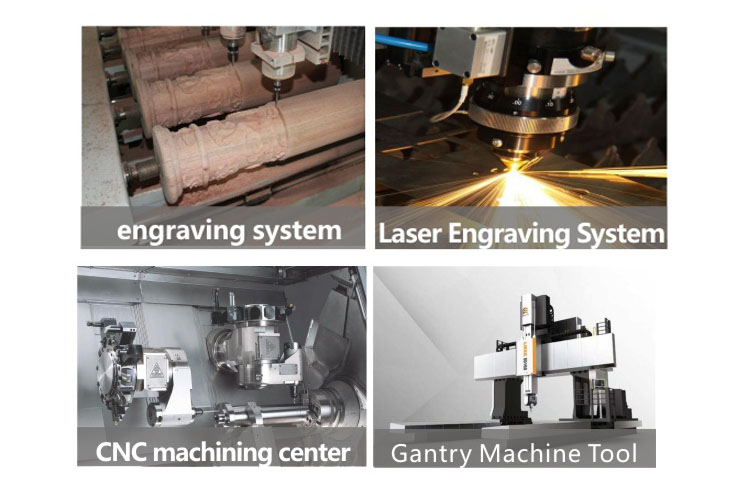

2.Raon tagraidh

Tha smachd iomallach Crang Panc air a chleachdadh gu farsaing ann an diofar raointean Ciùc mar shiostam gràbhaladh laser, Inneal bleith CNC, PNC Machiness, Inneal inneal Gantry, msaa.

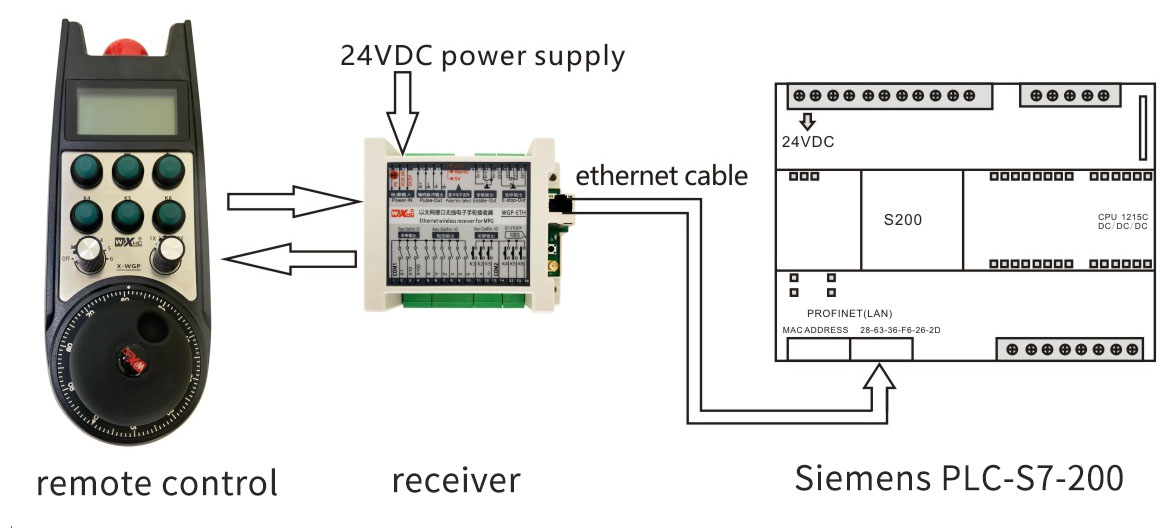

3. Ro-ràdh don Phrionnsapal obrach

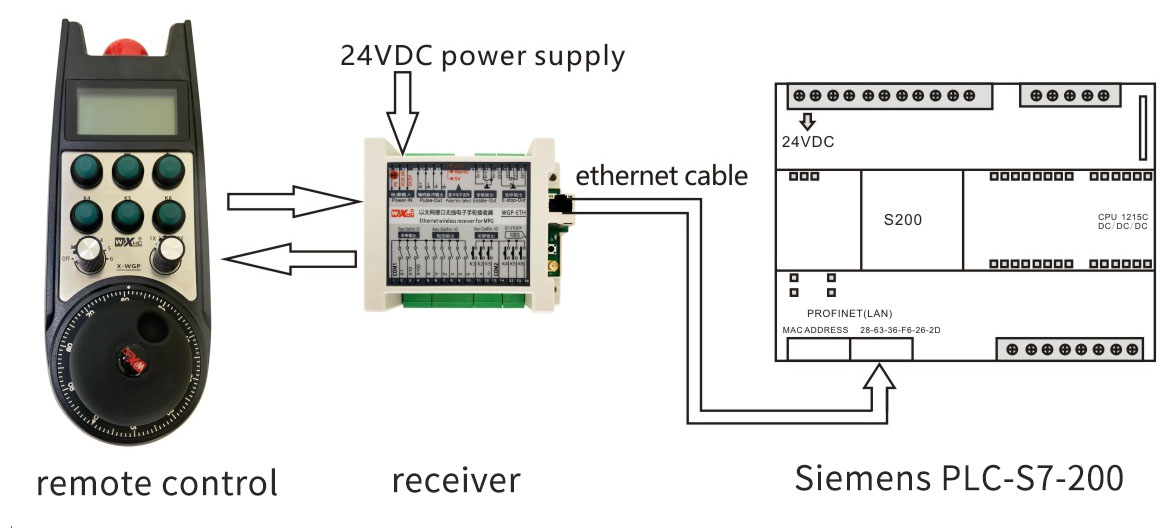

1) Tha aon-làimhe dealanach ceangailte ri plc tro ghlacadair Ethernet

A.Tha whewomeel a 'cur thairis air a' phrìomh dàta gun uèir gu bràth don ghlacadair, agus bidh an glacadair a 'sgrìobhadh na h-iuchraichean tron t-siostam Plc Siostam DB Càball Lìonra; Bidh an glacadair a 'leughadh an dàta a thaisbeanadh bhon sgìre DB ainmichte, agus an uairsin a 'tilleadh an dàta gu scrion taisbeanaidh làimhe. Faodaidh an neach-cleachdaidh seòladh bunaiteach de sheòladh Stèidhichte agus a 'sgrìobhadh sgìre DB a ghnàthachadh air an àm-làimhe, gus an urrainn don chnabh-làimhe an dàta a leughadh agus a sgrìobhadh ann an sgìre DB den PLC.

b. Tha an cuidhteas a 'toirt taic do Siemens S7 protocol. A 'buntainn ri plc s7-200, Plc S7-300 agus plc s7-1200.

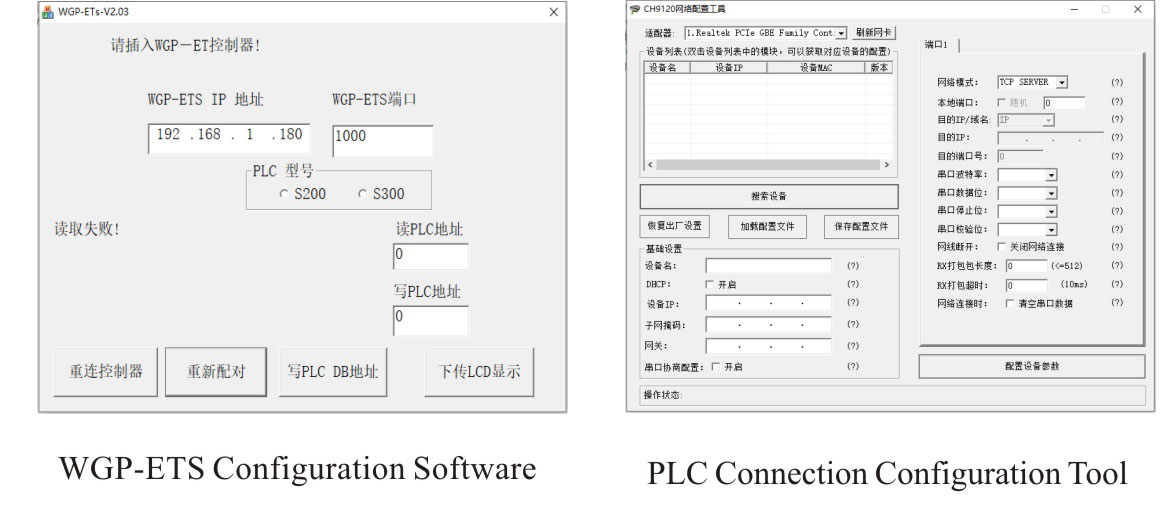

c. Faodaidh an neach-cleachdaidh an cuidhteas a rèiteachadh gu modh frithealaiche agus modh teachdaiche tro inneal rèiteachaidh ceangail Plc.

Ann am modh an fhrithealaiche, Bidh an neach-cleachdaidh a 'rèiteachadh an PLC a' leughadh agus a 'sgrìobhadh seòladh tro Bhathar-bog WGP-ENGS;Cleachd inneal rèiteachaidh ceangail PLC gus an glacadair a chuir a-steach don mhodh cliù. Às deidh rèiteachadh, Faodaidh glacadair XWGP-ETS conaltradh leis a 'PLC tro phròtacal àbhaisteach SDA.

2)Iarrtas sònraichte

Toradh sònraichte de ghlacadair-làimhe agus Siemens plc S7-200:

a. Tha am putan air an àm-làimhe a 'freagairt ri luach a' bhoool a chuir an neach-cleachdaidh anns a 'PLC. Ma thèid am putan an làimhe làimhe a bhrùthadh, Tha an raon bolto a tha co-fhreagarrach fìor, agus nuair a thèid a leigeil ma sgaoil, tha e meallta, agus faodar seòladh bonn bunait a 'bhool a stèidheachadh tron chiad-làimhe;

b. Faodaidh an tùs-làimhe luach a bhith aig luach an sgìre DB anns a 'PLC. Tha aon axis 4 bytes de dhàta taisbeanaidh, agus 6 Tha iomlan de 24 bytes. Faodar seòladh bonn an sgìre DB a shuidheachadh tro Bhathar-bog Cligidh WGP-ENTS.

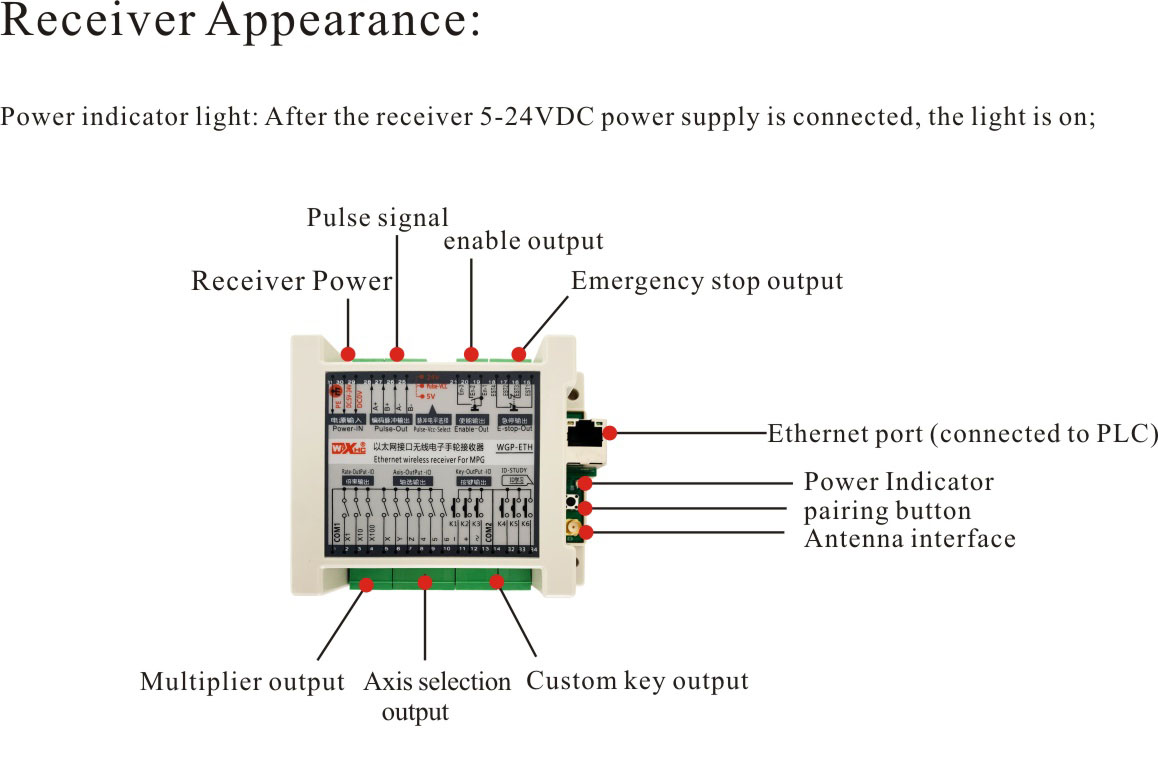

4.Sealladh Ro-ràdh

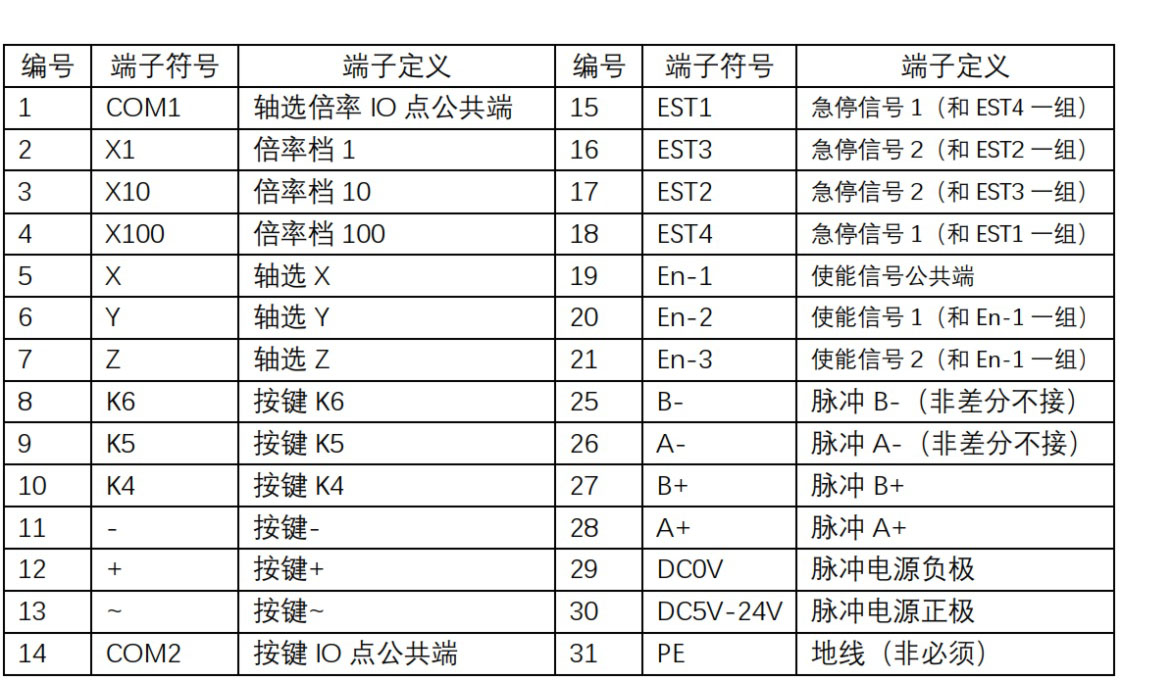

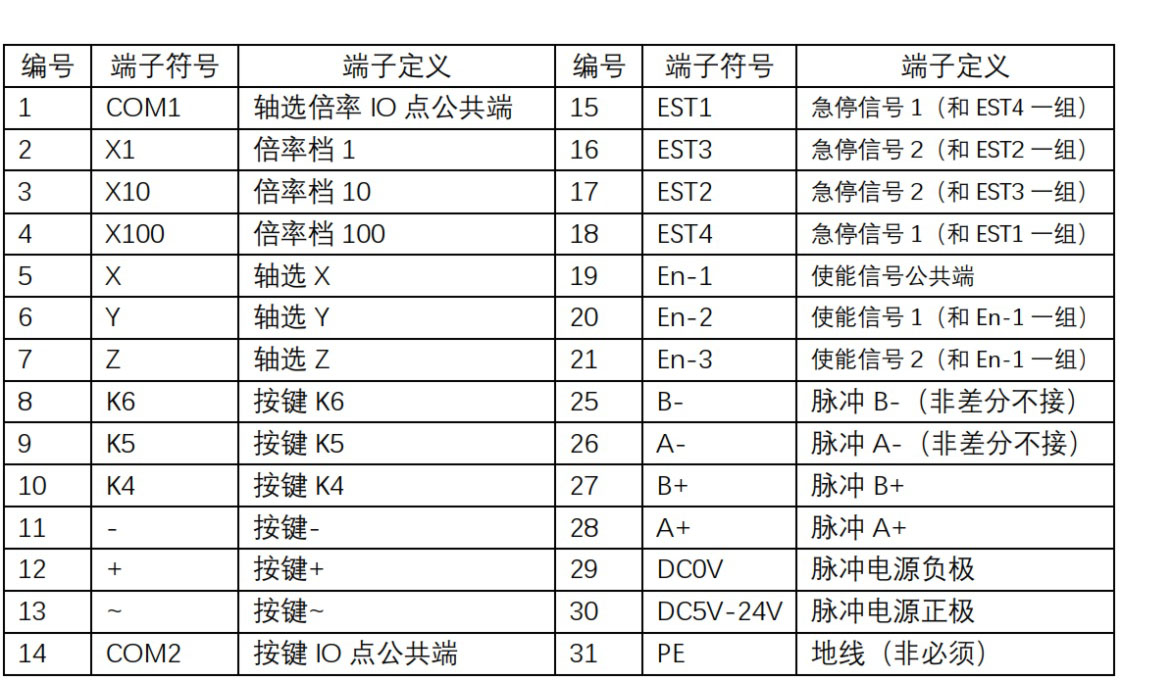

5.Clàr-leulain crìochnachaidh a 'chuirp agus a' chladh

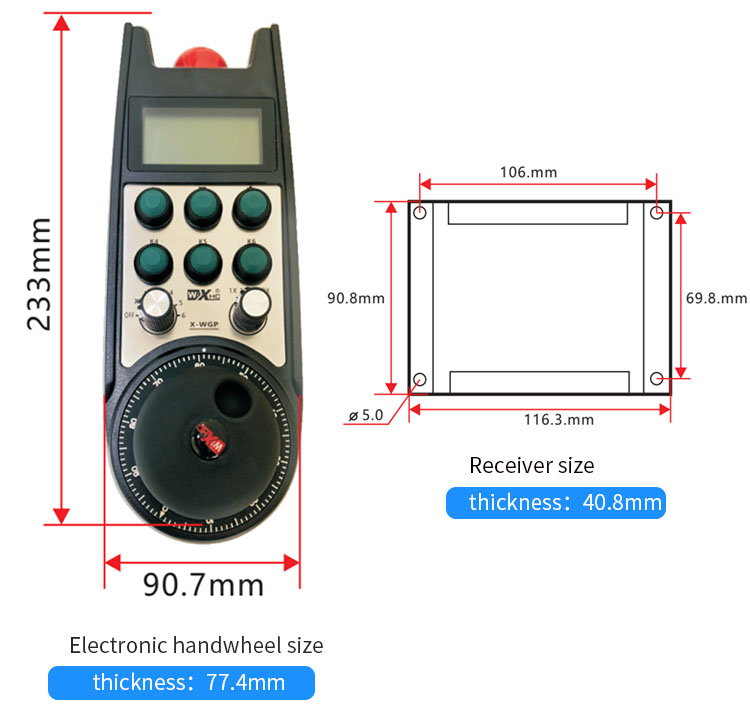

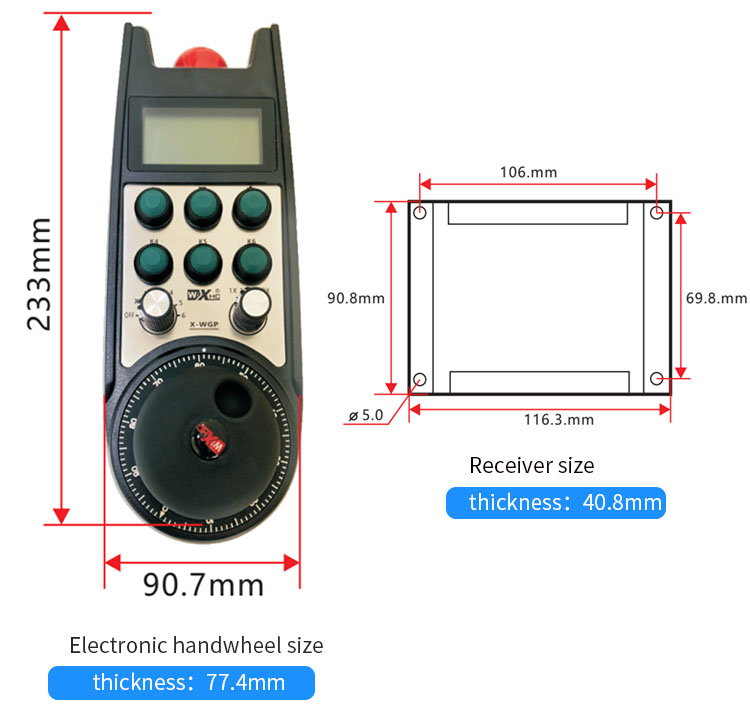

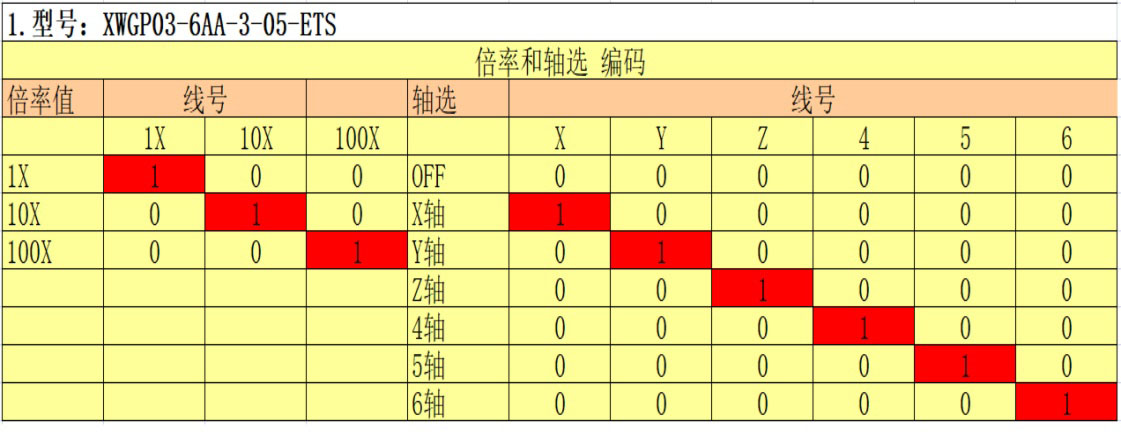

6.Meud Ciallachd